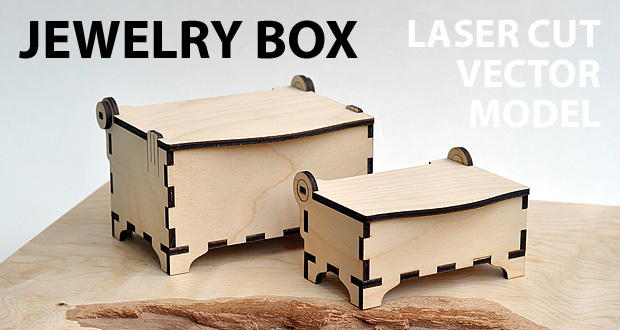

White engraving or inversion engraving.

Objectives

To obtain white engraving, you must remove thin dark layer of the coating from product and prevent charring of wood.

To achieve this effect, high speed and low laser power are needed.

Preparing wooden blank

Apply dark stain to wooden blank (plywood, veneer,…), then varnish. Dry and grind wooden blank.

Use spray paint or other options.

Laser machine parameters*

*Suitable for 40 watt laser machine

- Speed: 300-400 mm / sec

- Maximum power: 12-13%

- Interval: 0.05-0.1 mm

You may to play with parameters of your laser machine.

Post processing

After fast and low-power engraving almost no soot on product.

Soot from the cutted edges of the product can be easily removed with damp sponge soaked in water.

Apply varnish to product after drying.

Conclusion

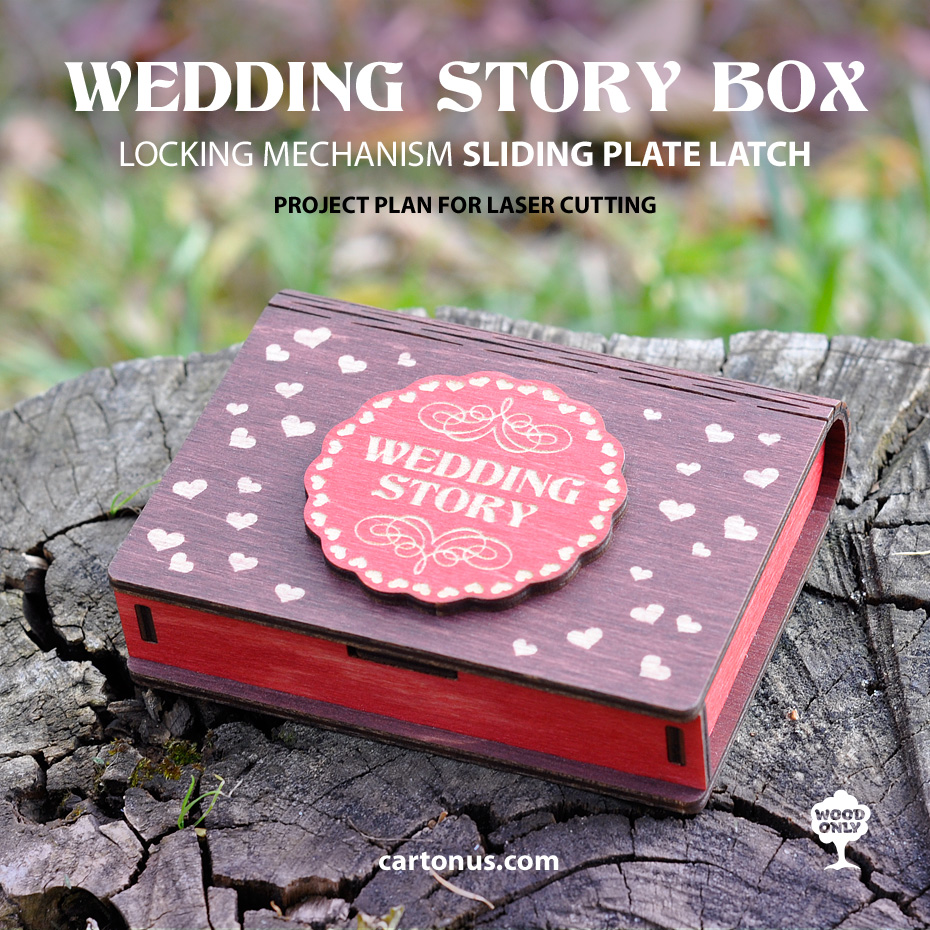

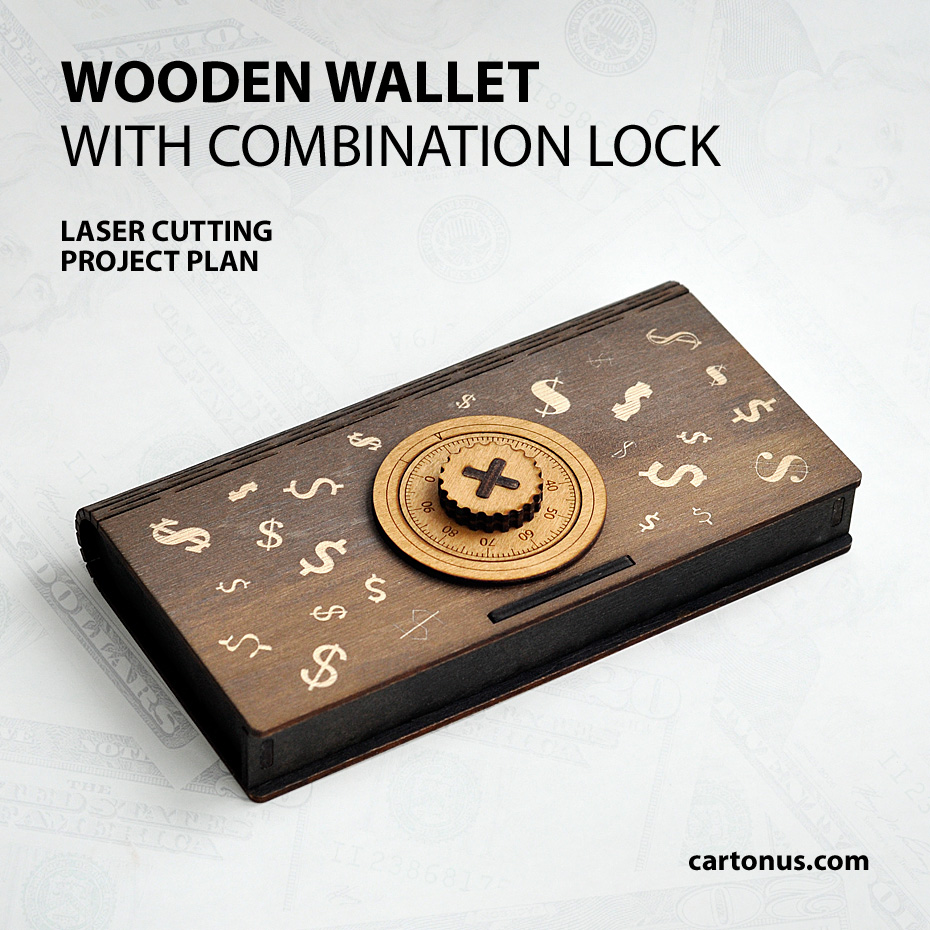

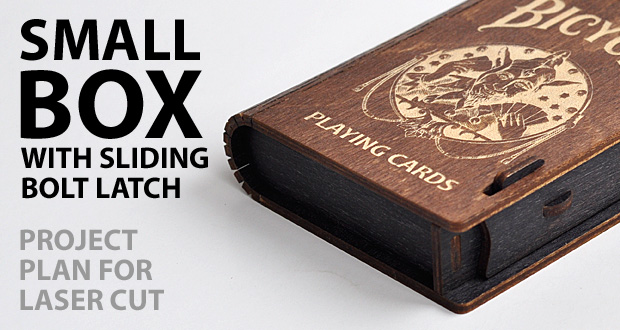

Effect of white (inversion) engraving is stunning.

In this way we are make many projects.

No responses yet